Precision Manufacturing

and Engineering Equipment Solutions

Anchorcut excels in complex projects with

comprehensive industry capabilities, including metal parts

and industrial equipment manufacturing, assembly, and

surface treatment.

Precision Manufacturing and Engineering Equipment Solutions

Anchorcut excels in complex projects with comprehensive industry capabilities, including metal parts and industrial equipment manufacturing, assembly, and surface treatment.

Structrure Steel Parts

Structrure Steel Parts

Learn MorePipe Spools and Skid Units

Pipe Spools and Skid Units

Learn MorePressure Vessels

Pressure Vessels

Learn MoreMetal Machinery Parts

Metal Machinery Parts

Learn MoreMarine Accessories

Marine Accessories

Learn MoreAutomation Equipment

Automation Equipment

Learn MoreOne-Stop Solution Provider

Anchorcut is always committed to providing users with more competitive products and more personalized and comprehensive services.

- Experienced Support

- Controlled Process

- Global Industrial Chain

Industries We Served

Automotive

Medical

Energy

Oil & Gas

Aerospace

Robotics

Marine & Ship Building

Agriculture

Construction Equipment & Machinery

Defense

What Makes Us Unique

We are your premier one-stop solution provider, dedicated to saving your procurement time

Experienced Engineer Support

Anchorcut has an experienced team of engineers with mechanical, electrical, automation, welding, logistics packaging, and other capabilities to deliver tailored solutions in equipment manufacturing for our clients. Moreover, we foster close collaborations with local professional universities to absorb and nurture creative young talent.

Controlled Manufacturing Process

We consistently adhere to the principle that quality is crafted, not merely checked. Each on-site employee undergoes rigorous standardized operation training to ensure proficiency. These standardized procedures not only regulate and control our production process but also serve as crucial assurances for maintaining quality standards and meeting delivery deadlines.

Comprehensive Industrial Chain

Situated in Yantai, we benefit from a fully developed industrial ecosystem. Here, diverse sectors including automotive, chemical, energy, heavy machinery, medical, electronics, semiconductor, food, and construction. Leveraging this robust industrial network, we excel as a top-tier service provider with exceptional resource integration capabilities to tailor your solution.

Efficient Logistics Solution

To provide cost-effective and protective packaging solutions for clients, we have experienced packaging engineers to design protective packaging for shipments. Also positioned at a key port hub in Northeast Asia, we can provide convenient logistics services to meet the precise needs of our customers.

Our Facility

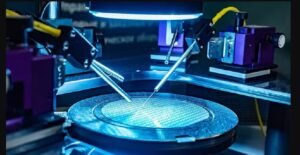

CNC Facility

Coating Facility

Eastern Welding Facility

Central Welding Facility

Accreditations

Achieving Perfection in One Go: Commitment to Quality

We firmly believe that quality is produced during the manufacturing process rather than the inspection process. We meticulously control process stability through professional planning, detailed operating specifications, and employees’ methodical and meticulous work. It’s the core for us to avoid quality issued from the first place.

They Believe in Anchorcut

Visit Anchorcut

Latest Post

Why Precision CNC Machining is Your Best Bet for High-Volume and High-Precision CNC Components

When it comes to manufacturing high-volume and high-precision CNC components, precision isn’t just a buzzword—it’s an absolute necessity. Industries like aerospace, automotive, and medical devices demand components that fit together flawlessly, often down to fractions of a millimeter. If you’re a purchaser looking for the most reliable and efficient way

6 Key Factors Affecting the Cost of Custom Welded Steel Structures and How to Budget Smartly

Discover how to budget effectively for custom welded steel structures. Learn key factors that impact cost, from material selection to welding methods, and get expert tips on saving without sacrificing quality. Start planning your project today!

How to Choose a Reliable High Precision CNC Machining Partner

Looking for a reliable high precision machining partner? Discover key qualities, essential capabilities, and integrated services like welding, surface treatments, and design support to ensure your project’s success. Learn how to choose the right partner for seamless, high-quality production.

Precision CNC Machining for Semiconductor Equipment: Challenges and Solutions

In the world of semiconductor manufacturing, precision CNC machining is indispensable for producing high-quality equipment. As semiconductor devices continue to shrink in size and increase in complexity, the demand for ultra-precise, reliable machining processes has never been greater. From basic milling and turning to advanced electrical discharge machining (EDM) and

Expert CNC Machining: Small Batch, Multi-Material, Multi-Process Solutions

In the rapidly evolving landscape of modern manufacturing, the demand for customized small batch, multi-material, multi-process CNC machining has surged, especially in industries like optics, semiconductors, automation, and highly customized equipment. At AnchorCut, we pride ourselves on offering highly customized multi-process and multi-material manufacturing solutions tailored to meet the specific

Precision Machining Insights: Ceramic and Tungsten Steel Parts

In today’s fast-paced and demanding technological landscape, industries such as military and semiconductors rely heavily on precision-engineered components that offer durability, performance, and reliability. Ceramic and tungsten steel parts have become increasingly essential in these sectors due to their unique properties, enabling them to withstand extreme environments and deliver high