Pressure Vessels

Pressure Vessels

With years of experience of producing pressure vessels, we win the reputation by providing low cost but high quality products to our clients. We possess the capability to perform welding using manual, semi-automatic, and robotic techniques, including MIG/MAG, GTAW, SAW, SMAW, and FCAW processes. Understanding the stringent standard of pressure vessel industry, we strictly adhere to the ASME requirements. Our expertise in engineering and fabrication allows us to ensure precision, durability, and efficiency in every project we undertake.

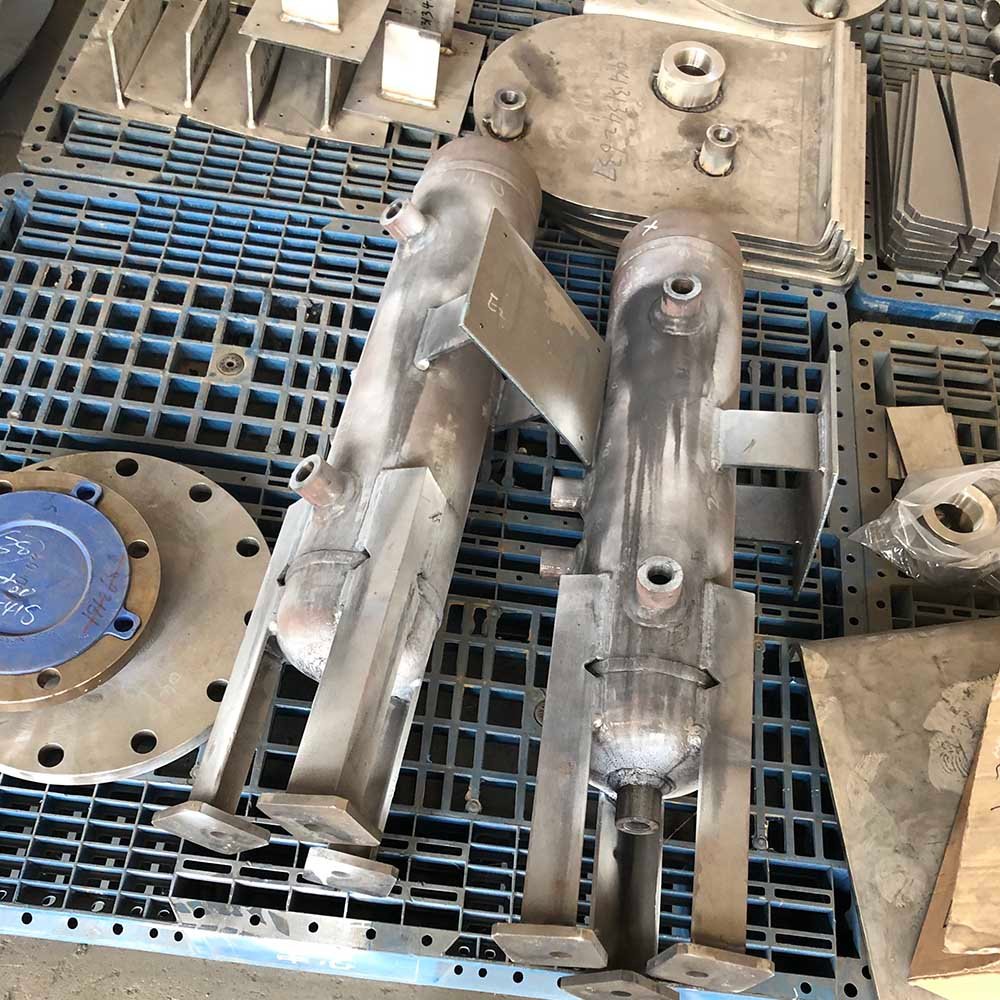

Successful Pressure Vessels Projects

Quality is at the forefront of everything we do. From material procurement to final inspection, we maintain rigorous quality assurance protocols to ensure that every pressure vessel meets the highest standards of safety, reliability, and performance. Our commitment to quality is deeply embedded in our values.

Providing Testing and Documentation Support

Anchorcut can provide non-destructive testing (NDT) such as PT, UT, MT, and RT as per customer requirements. We offer hydrostatic testing and leak-tightness verification, along with relevant reports including material reports, dimensional inspection reports, pressure testing reports, NDT reports, WPS (Welding Procedure Specification), and PQR (Procedure Qualification Record).

Adherence to ASME Standards

We can conduct product manufacturing in compliance with ASME standards as specified in Sections I, IV, VIII-1, VIII-2, VIII-3, X, and XII. Our services can meet the requirements for welder qualification and welding procedure qualification as per ASME standards.

Variety of Welding Methods

We can provide welding methods such as MIG, GTAW, SAW, SMAW, and FCAW as per process requirements. Our team includes multiple welding engineers and senior welders with over 30 years of experience, capable of analyzing and resolving all issues that may arise during the welding process.

Pressure Vessel

Situated in Yantai, we benefit from a fully developed industrial ecosystem. Here, diverse sectors including automotive, chemical, energy, heavy machinery, medical, electronics, semiconductor, food, and construction. Leveraging this robust industrial network, we excel as a top-tier service provider with exceptional resource integration capabilities to tailor your solution.

Capabilities in Welding and Fabrication

At Anchorcut, Our welding proficiency encompasses a broad spectrum of techniques, both manual and automated, ensuring flexibility and precision in our projects. The techniques include:

Metal Inert Gas/Metal Active Gas Welding

Metal Inert Gas/Metal Active Gas Welding: Ideal for high productivity and efficiency.

Gas Tungsten Arc Welding

Provides superior control for intricate tasks.

Submerged Arc Welding

Ensures deep penetration and minimal contamination.

Shielded Metal Arc Welding

Versatile and widely applicable for various conditions.

Flux-Cored Arc Welding

Combines the benefits of MIG and SMAW for robust performance.

Finishing Services

Your structural steel parts will undergo finishing in our eastern dedicated painting workshop. Our high-performance equipment can handle all industrial painting, powder coating, or sandblasting, providing the necessary profiles for your project.

Paint and Sandblasting Room Sizes:

Paint Booths:

- 15m * 5m * 5m

- 20m * 15m * 10m

Sandblasting Rooms:

- 15m * 5m * 5m

- Equipped with a continuous shot blasting reclaim system

- Capable of sandblasting carbon steel, stainless steel, and aluminum

Successful Pressure Vessels Projects