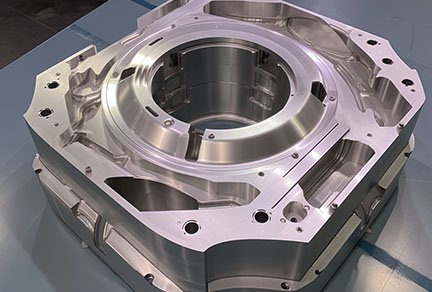

Precision CNC Machined Vacuum Chambers for High-Stakes Industries

Anchorcut’s stainless steel and aluminum products for vacuum-related applications serve numerous markets and industries, including vacuum science, photovoltaics, defense, semiconductors, nuclear energy, automotive, aerospace, and research and development.

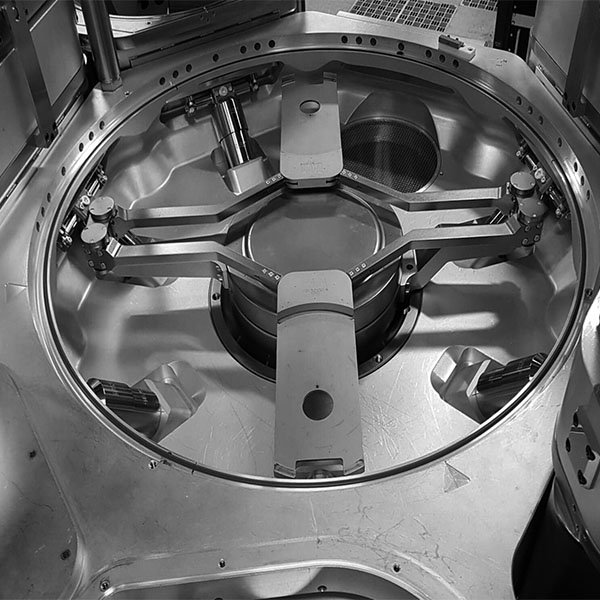

Semiconductor process chambers

Surface analysis chambers

Surface deposition chambers

Preparation chambers

Radial distribution chambers

Transfer chambers

Load locks

Let's work together!

Already have a project in mind? Contact us today to discuss your idea.

Advantages of Anchorcut vacuum chambers

Anchorcut has extensive experience in customizing chambers for both high vacuum (HV) and ultra-high vacuum (UHV) industries.

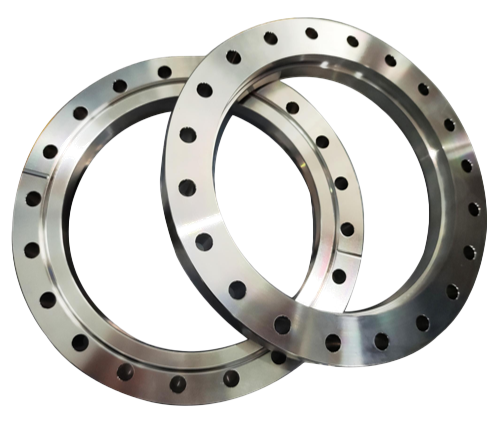

We stock vacuum components, such as vacuum flanges, fittings, and valves, available for use in the design and manufacturing of vacuum chambers.

Our outstanding machining capabilities and ample manufacturing space enable us to handle large-scale vacuum chamber production.

Comprehensive Vacuum Chamber Manufacturing Services with Precision and Expertise

Our state-of-the-art vacuum chamber manufacturing facility offers a wide range of services, including MIG and TIG welding, CNC machining, orbital welding, rolling, precision fabrication, complete custom vacuum chamber system finishing, and inspection.

Expert Engineering Support from Initial Drawings to Full-Scale Production

We boast a highly skilled team of engineers who provide support from the initial drawings and technical consultations all the way through to full-scale production of custom vacuum chambers for both standard and UHV applications. Anchorcut ensures that every product meets aesthetic, material composition, and other critical specifications. If you already have chamber designs, our “build-to-print” service guarantees high-quality, precise replication.

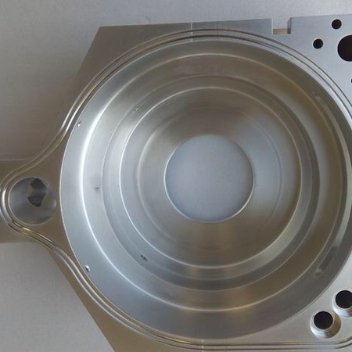

In-House, Rigorous Manufacturing Processes for High-Quality UHV Chambers

All manufacturing processes—including sheet cutting, machining, welding, cleaning, assembly, and leak testing—are completed in-house. During the welding process, each port is calibrated to ensure accurate fitting of various accessories. We also offer electro-polished and standard UHV degassed chambers. To prevent residual contamination from cutting fluids during machining, multiple cleaning procedures are carried out post-cutting, followed by a rigorous inspection SOP. After successfully passing helium leak testing, the UHV chambers undergo a final cleaning and are carefully packaged for delivery.

Vacuum Chamber Products Showcase

Explore a realm where your ideas come to life with exceptional precision, powered by our state-of-the-art vacuum chamber fabrication. Our extensive portfolio showcases our dedication to excellence, featuring custom vacuum chambers expertly crafted by our skilled team. If you’re in search of the pinnacle of vacuum chamber customization, Anchorcut Precision is your final destination. Collaborate with us, and let’s shape the future together.