When it comes to manufacturing high-volume and high-precision CNC components, precision isn’t just a buzzword—it’s an absolute necessity. Industries like aerospace, automotive, and medical devices demand components that fit together flawlessly, often down to fractions of a millimeter. If you’re a purchaser looking for the most reliable and efficient way to meet these requirements, precision CNC machining is the solution you’ve been searching for.

Let’s explore why CNC machining is the gold standard for producing high-volume and high-precision CNC components and how it can transform your supply chain.

Understanding High-Volume and High-Precision CNC Components

What Are High-Volume and High-Precision CNC Components?

High-precision components are parts manufactured to meet extremely tight dimensional specifications. Tolerance refers to the allowable deviation from a specified dimension—typically measured in microns or thousandths of an inch. For example, a tolerance of ±0.001” means the part must be within one-thousandth of an inch of the target measurement.

High-volume production refers to the capability of manufacturing these precise components at scale without sacrificing quality or consistency. This combination is critical in industries where even the smallest deviation can compromise safety, performance, or functionality. Think of turbine blades in an aircraft engine or surgical instruments used in life-saving procedures—there’s no room for error.

Why High-Precision and High-Volume Matter

In high-stakes industries, poorly manufactured components can lead to:

- Product failures that damage your brand reputation.

- Costly recalls that disrupt your operations.

- Safety risks that endanger lives.

Precision CNC machining eliminates these risks by delivering parts that meet exacting standards at scale, ensuring reliability and peace of mind.

Why Choose CNC Machining for High-Volume and High-Precision CNC Components?

The Power of CNC Technology

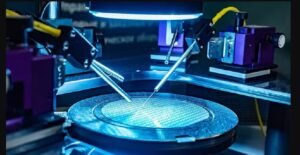

CNC (Computer Numerical Control) machining uses computer-guided tools to manufacture parts with unmatched precision. Unlike manual machining, CNC technology automates the entire process, ensuring accuracy, consistency, and efficiency. From simple designs to complex geometries, CNC machines can handle it all.

Here’s why CNC machining is the ideal choice for high-volume and high-precision CNC components:

Precision and Accuracy

CNC machines operate with exceptional precision, often achieving tolerances as tight as ±0.0001”. Computer-controlled systems minimize human error, allowing you to trust that every part will meet your exact specifications. Whether you’re producing a single prototype or thousands of identical parts, CNC machining delivers consistent results every time.

Versatility in Materials

Need parts made from stainless steel, titanium, or advanced composites? CNC machining handles a wide variety of materials, making it versatile enough for almost any application. This flexibility is essential when working with materials that must meet both strength and precision requirements.

Complex Geometries Made Easy

From intricate medical implants to multi-faceted aerospace components, CNC machining excels at creating complex shapes. Advanced 5-axis CNC machines can rotate parts along multiple axes, enabling the production of parts with detailed features and tight corners.

Key Benefits of Precision CNC Machining

1. Consistency and Repeatability

When you need hundreds or thousands of identical parts, CNC machining ensures they are produced with the same precision every time. This level of consistency is vital for high-precision components that must fit together seamlessly in larger assemblies.

2. Faster Turnaround Times

CNC machining’s automated processes speed up production without compromising quality. Once the program is set up, machines can run continuously, reducing lead times and helping you meet tight deadlines.

3. Reduced Waste and Cost Efficiency

While the initial setup cost of CNC machining may be higher, it’s offset by reduced material waste and long-term efficiency. Precision machining ensures optimal material usage, saving money in the long run.

4. High Scalability

CNC machining is perfect for both low-volume prototypes and high-volume production runs. Once the initial design is programmed, scaling production is straightforward and cost-effective.

How to Choose the Right CNC Machining Supplier

Not all CNC machining services are created equal. Here’s what to look for when selecting a supplier for your high-volume and high-precision CNC components:

Expertise and Experience

Partner with a supplier that specializes in high-precision components. Experienced suppliers understand the nuances of tight tolerances and can offer valuable insights to improve your designs and processes.

Advanced Equipment

The best results come from state-of-the-art CNC machines. Look for suppliers equipped with 5-axis machines, multi-tasking machining centers, and advanced inspection tools like Coordinate Measuring Machines (CMMs).

Quality Assurance Processes

A reliable supplier will have rigorous quality control procedures in place. This includes:

- Regular calibration of machines.

- Use of advanced measurement tools for inspection.

- Documentation of quality checks for full transparency.

Customization and Support

Your supplier should be able to customize parts to meet your specific needs. They should also provide clear communication, quick responses to questions, and proactive support throughout the project.

Real-World Applications of Precision CNC Machining

Aerospace: High-Precision Turbine Blades

In the aerospace industry, turbine blades must withstand extreme temperatures and pressures while maintaining precise dimensions. CNC machining ensures these components meet strict specifications, enhancing both safety and performance.

Medical Devices: Intricate Surgical Instruments

Medical devices demand flawless precision to ensure patient safety. CNC machining produces surgical tools and implants with tight tolerances, smooth finishes, and biocompatible materials.

Automotive: Engine Components

From pistons to fuel injectors, automotive parts require high precision for optimal engine performance. CNC machining delivers parts that improve fuel efficiency and reduce emissions.

Challenges in Precision CNC Machining (and How They’re Solved)

Material Challenges

Some materials, like titanium and high-carbon steels, can be difficult to machine due to their hardness. Advanced cutting tools and optimized machining strategies overcome these challenges, ensuring precision without compromising material integrity.

Tool Wear

Continuous machining can lead to tool wear, affecting accuracy. Regular maintenance and the use of high-quality tooling mitigate this issue, ensuring consistent performance.

Cost Considerations

While CNC machining can be costlier upfront, its efficiency and precision make it a worthwhile investment. Partnering with an experienced supplier can help optimize costs without sacrificing quality.

Conclusion

Precision CNC machining is the ultimate solution for producing high-volume and high-precision CNC components. Its unmatched accuracy, consistency, and versatility make it the go-to choice for industries where precision is non-negotiable. By choosing the right CNC machining partner, you can ensure your components meet the highest standards of quality and performance.

Ready to elevate your manufacturing process? Contact us today to discuss your project and see how precision CNC machining can benefit your business.