In the rapidly evolving landscape of modern manufacturing, the demand for customized small batch, multi-material, multi-process CNC machining has surged, especially in industries like optics, semiconductors, automation, and highly customized equipment.

At AnchorCut, we pride ourselves on offering highly customized multi-process and multi-material manufacturing solutions tailored to meet the specific needs of various industries. We excel in ensuring product quality while meeting tight deadlines, thanks to our flexibility, innovation, and precision.

Our Expertise in Materials:

We work with a broad spectrum of materials, including:

– Carbon steel

– Stainless steel

– Aluminum alloy

– Titanium alloy

– Brass

– Copper

– Ceramic

– Tungsten steel

– Graphite

– Teflon

– PEEK

– PE

This wide selection allows us to meet the diverse material requirements of our clients, ensuring flexibility in applications.

Comprehensive Manufacturing Processes:

Our full range of machining and manufacturing processes include:

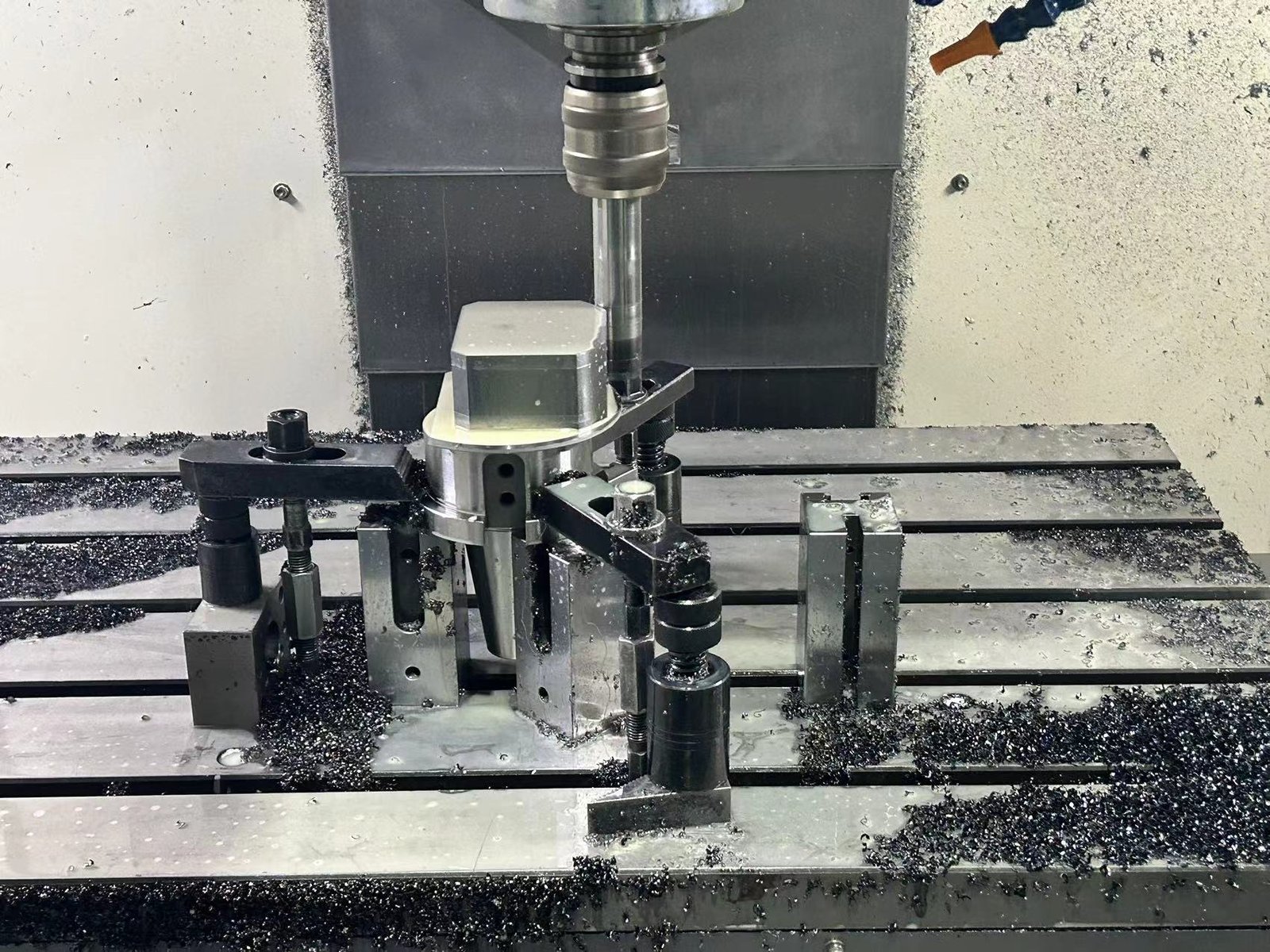

– CNC milling

– CNC turning

– Wire cutting

– Laser cutting

– EDM (Electrical Discharge Machining)

– Bending

– Drilling

– Grinding

– Heat treatment

– Laser welding

– TIG welding

Surface Treatments:

To enhance durability and appearance, we offer surface treatments such as:

– Electroplating

– Painting

– Anodizing

– Sandblasting

– Shot peening

– Passivation

– Ultrasonic cleaning

– Acid pickling

– Galvanizing

– Dacromet coating

We offer both multi-material expertise and multi-process capabilities, providing clients with a one-stop solution for all machining and manufacturing needs.

Key Industry Applications:

1. Optics Industry:

In optics, high surface precision and specialized materials are critical. Small batch manufacturing is ideal for producing customized optical lenses, holders, and fiber optic components. We meet the high standards of optical instrument manufacturers and research institutions by delivering precise parts on time.

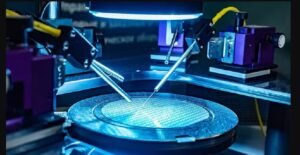

2. Semiconductor Industry:

Semiconductors require strict precision, material properties, and surface treatments. We specialize in producing custom parts for semiconductor equipment, including chip testing fixtures and laboratory tooling, ensuring that we meet the industry’s stringent standards.

3. Medical Device Industry:

In the medical field, precision, reliability, and biocompatibility are paramount. We manufacture custom surgical instruments, implants, and diagnostic components using materials like stainless steel and titanium, ensuring adherence to the highest hygiene and quality standards.

4.Aerospace Industry

The aerospace industry demands high-strength, lightweight materials and precision components that meet rigorous safety and performance standards. Our company specializes in producing small-batch custom parts for aircraft, drones, and spacecraft, including engine components, structural parts, and fasteners. With multi-material and multi-process capabilities, we deliver parts that meet the stringent requirements of aerospace manufacturers and research agencies.

5.Defense Industry

The defense industry requires parts with exceptional durability, strength, and precision for critical military applications. We specialize in producing custom components for military vehicles, weapons systems, and communication equipment, using robust materials like carbon steel, titanium, and composites. Our multi-process approach ensures that we meet the exacting standards of defense contractors and government agencies, delivering reliable parts for mission-critical operations.

6.Consumer Electronics Industry

The consumer electronics industry demands small, intricate, and high-precision components made from a variety of materials. We manufacture custom parts for devices such as smartphones, wearables, and home electronics, focusing on components like connectors, enclosures, and heat sinks. Our ability to deliver small-batch, multi-material parts with precise tolerances ensures that we meet the fast-paced needs of the consumer electronics market.

Advantages of Our OEM Small Batch CNC Machining:

– Flexibility in Design and Development:

Our team quickly adapts to changes in customer requirements, offering innovative design solutions and consultation to optimize manufacturing processes.- Agile Supply Chain Management:

We maintain a responsive supply chain, ensuring timely delivery of raw materials and components through strong supplier relationships.

– Customer Relationship Management:

We ensure effective communication with clients, providing outstanding after-sales service, technical support, and quick responses to feedback.

-Strict Quality Control

We adhere to stringent quality control processes, ensuring that each product meets the highest industry standards. We believe the quality issue is prevented from the beginning. And you can count on us for the high quality but cost-effective solution.

-Advanced Technology and Equipment

State-of-the-Art Production Equipment: We utilize cutting-edge equipment and technologies such as 5-axis CNC machines, automated production lines, and CAD/CAM systems to increase production efficiency and product quality.

Ongoing Technical Training: Our employees undergo regular technical training to ensure they stay proficient in operating advanced manufacturing technologies, delivering top-tier products consistently.

Frequently Asked Questions (FAQ):

1. What materials are best for CNC machining in small batches?

At AnchorCut, we work with a variety of materials, but the best material depends on the specific application. For example, aluminum is often preferred for lightweight components, while stainless steel and titanium are ideal for medical and high-strength applications.

2. What industries benefit the most from small-batch CNC machining?

Industries that require highly customized or complex parts in smaller quantities benefit the most from our small-batch CNC machining services. These include optics, semiconductors, medical devices, aerospace, and automotive industries.

3. How does AnchorCut ensure precision in multi-process machining?

We use advanced CNC machines that are capable of multi-axis operations, allowing for high precision in complex geometries. Our skilled technicians follow rigorous quality control processes, including in-process inspections, to ensure that each part meets the desired specifications.

4. Can AnchorCut assist with product design?

Yes, our in-house engineers and design team can assist with product design. We provide consultation and optimization services to ensure that your designs are manufacturable and cost-effective.

5. What turnaround times can I expect?

Turnaround times depend on the complexity and quantity of the parts ordered. However, our agile supply chain and efficient manufacturing processes enable us to provide competitive lead times, especially for small batch orders.

At AnchorCut, we understand the ever-changing demands of modern manufacturing. Our commitment to flexibility, innovation, and quality enables us to exceed client expectations across industries. Whether you are in optics, semiconductors, medical devices, or any other specialized industry, our team is dedicated to delivering high-precision parts tailored to your needs.

Ready to bring your ideas to life? Contact us today to discuss your custom CNC machining project!